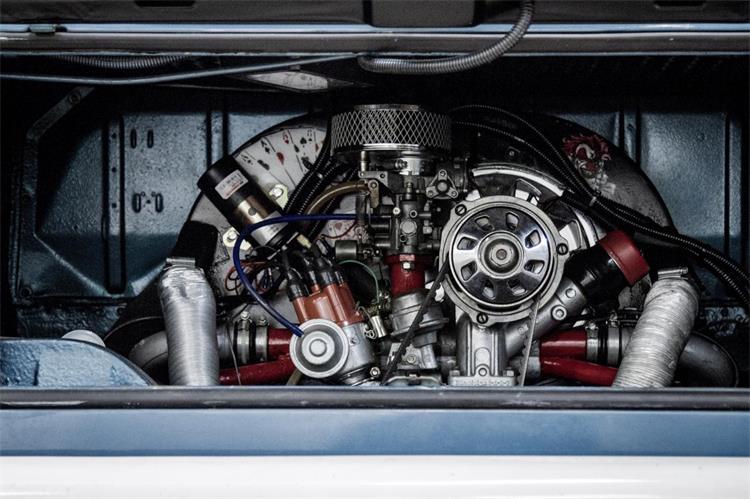

In the automotive industry, the importance of part identification and traceability cannot be overstated. Recalls due to faulty parts can cost manufacturers millions and damage their reputation. One of the key technologies enabling accurate part identification is the use of 2D barcodes, including QR codes and Data Matrix codes. When printed with an emphasis on accuracy and resilience, these codes become instrumental in guaranteeing the traceability of parts. This highlights the indispensable role of an industrial barcode printer, and iDPRT is at the forefront of providing these solutions in the automotive industry.

2D Barcodes in the Automotive Industry

Automotive components, ranging from small car sensors to large engine covers, are labeled with barcodes for identification. Typically, two-dimensional barcodes such as QR codes or Data Matrix codes are used. These barcodes often contain details like the part number, serial number, manufacturing date, and other specific data such as supplier information and batch numbers.

One might wonder, why not use the simpler one-dimensional barcodes? Compared to one-dimensional barcodes, the two-dimensional codes on automotive parts have a larger capacity, allowing them to store more information. Moreover, they have a strong error tolerance. Even if the barcode is partially damaged, the original data can still be retrieved through error correction mechanisms.

Printing these two-dimensional codes must also adhere to standards set by regional industry associations, such as the China Association of Automobile Manufacturers (CAAM), the Automotive Industry Action Group (AIAG) in the U.S., and the European Automobile Manufacturers’ Association (ACEA). Such standardization ensures that these barcodes can be universally read and understood, facilitating global trade and collaboration.

The iDPRT iX4P Industrial Barcode Printer

In the automotive industry, industrial-grade barcode printers are commonly used for printing barcode labels. These printers are designed to perform large-scale printing tasks in harsh work environments. They are typically more durable and faster in printing speed, capable of meeting the demands of large-scale production lines.

The IDPRT iX4P industrial barcode printer is one of best industrial barcode printers, widely recognized by users for its robust construction, an impressive 600-meter ribbon capacity, and efficient printing capabilities, making it adept at handling large-scale, intensive printing tasks in demanding work environments.

The iX4P barcode industrial printer supports printing on various label materials, including durable synthetic materials like PP and PE. These materials are commonly used for automotive QR code labels due to their effective resistance to high temperatures, humidity, chemical corrosion, and mechanical wear.

This 4-inch industrial-grade barcode printer offers a range of printing precision options, including 203dpi, 300dpi, and an ultra-high precision mode of up to 600dpi. This ensures that the printed barcodes are clear, compliant, and easily scannable. Additionally, the iDPRT printer’s advanced built-in chip and ample storage space ensure a smoother and more stable printing process.

Key features of the iX4P include:

● Rugged and Durable Design: The iX4P is built to last, with a design that can withstand the harsh conditions of an automotive manufacturing environment. It ensures stable performance even during long periods of continuous operation.

● High-Speed & High-Resolution Printing: The iX4P offers high-speed printing to keep up with the fast-paced production line. It supports printing resolutions of 203dpi, 300dpi, and 600dpi, ensuring every barcode is clear and readable.

● Versatile Material Compatibility: The iX4P is compatible with a variety of materials, including durable vinyl and synthetic materials like polyester and polypropylene. It can handle continuous paper, gap, black mark paper, punched hole labels, ECO thermal labels and etc.

● Ease of Operation: The iX4P features a 3.5-inch touchscreen, providing an intuitive user interface that simplifies the setup and operation of the printer. Additionally, the modular print head design is easy to replace, minimizing downtime and maintenance costs.

● Strong Compatibility and Versatility: The iX4P offers a variety of connectivity options, including Ethernet, USB, and serial interfaces, with optional WiFi support. It supports multiple printing protocols, including EPL, DPL, ZPL, ZPL-II, and TSPL, and is compatible with Windows, Linux, and MacOS.

In addition to the iX4P, iDPRT also offers a range of other industrial barcode label printers, including the iX4R 4-Inch Industrial RFID Barcode Printer. This RFID printer combines the benefits of barcode printing with the advanced capabilities of RFID technology, suited for applications where non-line-of-sight data capture is required, such as in warehouses or large automotive manufacturing facilities.

RFID technology is also being applied in the automotive industry. For instance, BMW uses RFID tags to track the production of engines in its Regensburg factory in Germany.

With ongoing advancements in the automotive industry, the need for effective and dependable barcode printing solutions is set to rise. iDPRT, with its array of superior industrial barcode printers, is strategically positioned to cater to this growing demand, aiding automotive manufacturers in enhancing their efficiency, quality, and profitability. Looking ahead, we anticipate iDPRT to continue its trailblazing journey, introducing even more innovative solutions in the realm of industrial barcode printing.